Hard to Decarbonise: Diesels

- Geoff Russell

- Dec 5, 2022

- 11 min read

This is the start of a series on hard-to-decarbonise parts of the global economy. The first part will be diesel engines and it will take a couple of posts. This, the first post, will be sketching the background to the problem.

Why are big trucks diesel and not petrol?

Have you ever thought about why big trucks are powered by diesel, rather than petrol, engines? Similarly for mining and earth moving equipment like bulldozers, tractors and the engines in big ships. They all have diesel engines; even if they also have an electric motor wrapped around the driveshaft! I’ll explain this below.

There are some exceptions, for example, ships which are nuclear powered, like submarines, icebreakers and aircraft carriers.

Have you ever thought about why?

What’s different about diesels? And will that affect our decisions for decarbonising them?

Diesels and oils

A few weeks back, Decouple’s guest was BF Randall (@Mining_Atoms). Decouple is a Canadian podcast (see appendix for details). You can find Mr Randall on Twitter and Substack. He tweets longish threads on energy issues and has a legal background working for big energy companies.

Mr Randall got me thinking about things I thought I understood reasonably well. He convinced me I didn’t. Time to go back to the drawing board.

I’ve always thought of the global transportation problem being mostly about cars. Globally, we sell about 2 million heavy trucks a year and 100 million cars. And sure, trucks are bigger and heavier, but there’s not that many of them. And then there’s things like tunnel boring machines, not too many of those either. And then there’s bulldozers and ships and monster mining trucks. There’s not that many of any of these, but add them up and the aggregate is surprisingly large.

How are we to power them? That was Randall’s topic.

Let’s start with some data to get a feel for the scale of the problem.

The scale of the problem

Here’s a breakdown of diesel and petrol consumption in 12 countries where there is good data (from the United Nations Framework Convention on Climate Change (UNFCCC) National Inventory).

Note that the above graph is an energy graph. You don’t need to know what a gigajoule is, it’s just an energy unit. So focus on the relative sizes of the petrol and diesel components. Are you as amazed as I was?

As you can see, there’s been plenty of progress reducing vehicle energy use (per person) over the past 30 years in most places. Amazingly, cars have become far more energy efficient to operate; despite being bigger. Note that the graph is energy per person from the two fuel sources. If it gave national totals, the US would swamp all the smaller countries.

How am I certain that the energy efficiency of vehicles has increased and that the decline isn’t from something like a smaller proportion of people driving, and more people using public transport? I’m not, but I doubt it. I don’t pay too much attention to cars and their engines, but the decline in big V8s can’t be missed. In any event, let’s just confirm by looking at total Australian total petrol and diesel energy use rather that the per person figure:

Our population has grown from 17 million in 1990 to 26 million today. But our total petrol use hasn’t expanded (much). Why not? Cars now are also much bigger than in the past, so why don’t they use more petrol? Diesel cars are less popular in Australia than Europe (see next graph) and even though today’s cars are bigger, their engines are much smaller. A Mazda CX5 is much bigger to look at than a 1990 Commodore, but is powered by a 2 litre engine with as much power as the 4 or 5 litre V8 that was fairly normal in the latter.

Okay, so in many countries, the per person energy use is now greater for diesel than for petrol (gasoline). That surprised me, but probably not Mr Randall or other experts who have their heads around these details.

When we look at carbon dioxide, the relativities of the situation don’t change, which shouldn’t be surprising; CO2 emissions are a very simple function of the energy in the fuel, so the graph is the same except that the units on the y-axis have changed! Diesels also produce other nasty pollutants and we will eventually have to think about those, but just not now.

We clearly need to decarbonise diesel engines every bit as much as petrol engines.

The last piece of problem scope data we look at is the split in use between types of machines. Most of these are on the next graph, which ignores petrol vehicles. I’ve also included all the non-road-transport fuels, meaning things that aren’t petrol or diesel. Namely domestic and international aircraft fuels and the fuel oils used for international shipping. These are called InternationalAir and InternationalShipping in the chart. We can’t really decide the relative importance of all the fuel decarbonising problems without understanding the relative use of all of them.

As you can see in the graph below, the difference between countries in the various categories is large. In Europe, diesel car registrations dropped markedly after VW’s diesel scam was uncovered in 2015. Diesel cars had been 60-70% of new car registrations in many parts of Europe in 2015, but dropped to 24-40% by 2019. In Australia, diesels are about a quarter of new car registrations in Australia today. It’s mainly heavy vehicles and long distance air travel that are dominating non-petrol fuel use in Australia.

It’s worth noting that the carbon dioxide from the two International categories aren’t included in our national emissions inventory. They are reported, but not added into the total. Climate change negotiators have been arguing about this for decades. Nobody wants them on their books.

Keep in mind that this is an energy graph, not an emissions graph; but the carbon dioxide from burning the oil is a function of the energy so it still gives us a sense of relativities.

Perhaps the most interesting thing about the above graph is the small size of the InternationalShipping ribbon. Do you remember the great food-mile furore? People busily buying local to save the planet rather than actually changing what they ate. It was and is, a terrific tactic for deflecting attention from the real climate problems with food, meaning meat – particularly ruminant meat.

Transport by ship is incredibly efficient in terms of both energy and carbon per tonne-kilometre. The carbon footprint of your food is almost entirely a question of what you eat, not where it comes from; unless of course, you move it by plane. I could ship lentils around the world many times and they’d still have a lower carbon footprint than beef from animals you kept and slaughtered in your backyard! The carbon footprint of ruminants like sheep and cattle is a function of land clearing (and foregone sequestration) and the methane, which is absolutely massive compared to the tiny transport emissions. People sometimes call aluminium “solid electricity” because of its high energy needs. But the story is the same, the median emissions per tonne of beef (67 tonnes of co2eq per tonne of product … t-co2eq/t), estimated for various farming methods, is about 4 times higher than for a tonne of aluminium (16.6 t-co2eq/t).

Ships move about 1.7 billion tonnes of stuff to and from Australia annually (about 180 kg per person per day) for that tiny InternationalShipping band at the bottom of the graph.

Now that we have a feel for the scale of the problem, let’s explain why diesels predominate in big machines.

Why are big machines mostly diesel?

Diesel engines endure. By comparison, petrol engines are cheap and nasty buzz boxes. Over 34 years between birth and the wrecker, my 1980 Mazda 323 had three engines. Had it have been a diesel, the original would have sufficed. Replacing all the world’s diesel machines with new machines before the old ones were worn out would be an extraordinary waste of resources; even if we efficiently recycled the steel, which we would.

The characteristic that allows diesels to endure is that they produce high torque at low revs. First let’s think about revs, meaning revolutions of the crankshaft per minute. Slow revs means less wear and tear. Diesels have fewer moving parts and the ones they have move much more slowly than in a petrol engine. Torque is a twisting force. Compare turning a stuck tap with your fingers to turning it with a 30cm-long spanner. The longer the spanner the more turning force you can exert. That’s torque. The magic of the diesel engine is getting high torque with minimal wear and tear on the engine.

You can skip the next two paragraphs if you don’t care about the how of it.

If you are a geek, you might enjoy this youtube clip of a guy powering a bicycle with a drone motor. The drone motor is thumb sized, but can put out 1000W. That’s not that much less power than an elite 90 kilogram Olympic bicycle track sprinter. The tiny drone motor achieves the power by spinning at almost 30,000 revs per minute. With the right gearing, you can move anything. But how long will your motor last?

How diesels achieve this is by careful attention to detail. First, the fuel they use has more energy per unit volume than petrol. Second, they don’t have a spark plug, but compress the fuel until that ignites it. The fuel is mixed with air, but with a higher ratio of air than a petrol engine and this changes the burning characteristics. It burns more evenly over more of the piston stroke. There’s a few more tricks in the mix, but I think I’ve given you enough of an idea.

The first piece of good news is that most diesels, especially big trucks, don’t just sit in garages most of the day. They work. This heavy use tends to make them wear out long before the engine needs replacing; so the fact that the engine will last a million kilometers doesn’t mean much when the rest of the machine will only last 30-50 years, or less. In Australia, the average age of heavy trucks is typically less than that of cars, despite their much higher workload.

The second piece of good news is that really big trucks, like mining trucks, are already electric; their diesel engine is only used to provide electricity, not motion. Motion and torque is provided by multiple electric motors. A big mining truck, like a Komatsu 980E, can haul 350 tonnes of ore. Its diesel generator provides 2610kW of power. A Rio-Tinto executive recently described the problem of using batteries:

“However, when we’re dealing with a 350-tonne haul truck, you have a slight problem: the battery is going to weigh 19 tonnes, and it will last for about 90 to 115 minutes,”

The problem isn’t replicating the diesel torque, an electric motor is, if anything, even better. The problem is that, as with EVs, batteries suck. Their energy density, despite decades of R&D, is still appalling. Wood can store about 5,000 watt-hours per kilogram compared to about 250 watt-hours for a good Lithium-ion battery. Dismal energy density is compounded with slow recharging rates, to make matters worse.

None of which makes batteries a show-stopper for big mining trucks, but getting to a feasible solution won’t be quick and easy. And then there’s the mineral supply chains. It’s terrific that Australia is now the world’s leading supplier of lithium, because some of the other suppliers have rather worse labour and environmental regulations, but that still leaves plenty of unsolved mining issues.

Ships are different from trucks, with many lasting much longer, despite the corrosive marine environment. Two thirds of cargo ships and half of all tankers are over 15 years old. Some of the biggest of the supertankers were built some 20 years ago and still in operation.

Oils ain’t oils

“Oils ain’t oils” is an old marketing slogan. But the differences in types of oil really matters when it comes to figuring out what to do with diesels; and more importantly, when to do it.

When you pump oil out of the ground, it’s a mix of thicknesses. Light oil, heavy thick sticky oil and everything in between. Ships typically run on the thickest oil, much thicker than diesel, which is itself thicker than petrol. “Thickness” is all about the length of the hydrocarbons. Long hydrocarbon means thick oil and thick oil means high energy per unit volume.

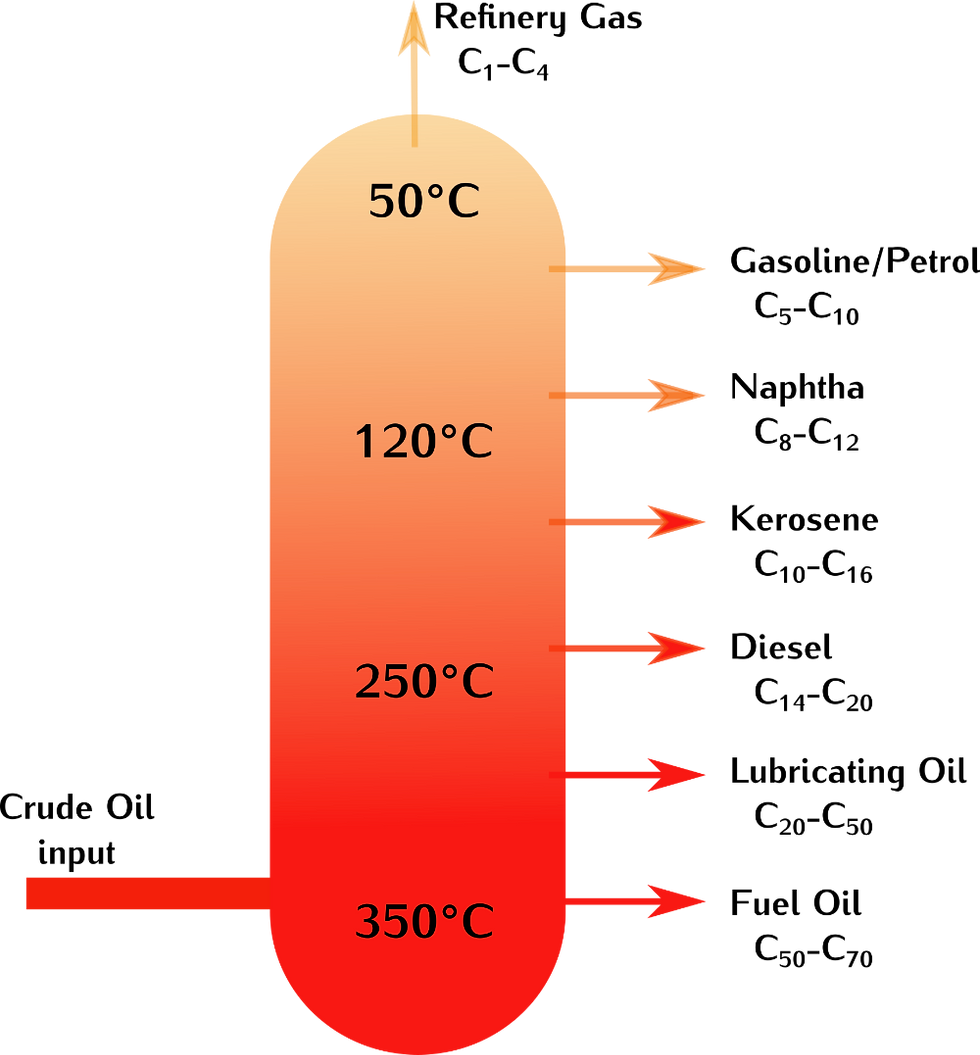

An oil refinery essentially distills and separates the grades of oil by the length of the hydrocarbon, as illustrated by the following image.

But this image doesn’t show the ratios of heavy to light oils. Different geologies produce different ratios of heavy to light fuels. When you pump up your oil, you get what you get; obviously. The types of impurities also differ and refineries are “adjusted” to handle oils from particular geologies. Switching your supplier isn’t trivial. Refineries used to handling Russian oil have had to be reconfigured to handle oil from elsewhere – Nigeria, Siberia, Arabia, Venezuela, Texas, whatever; they all have a range of characteristics.

In the US, for example, the average yield of a barrel of crude might be 44% petrol (gasoline) and 25% diesel.

Now can you see the problem if you handle petrol/gasoline cars before handling diesels?

If you are still running diesels and pumping crude oil to supply that diesel, you’ll be producing petrol whether you like it or not. It is just a co-product of the process. So if you keep pumping diesel, then there will be plenty of cheap petrol floating around making a switch to EVs (or hydrogen) harder. If we are pumping oil for the thickest fuel, for ships, then we’ll still be producing petrol and diesel.

We really need to solve all these problems in parallel, not in sequence.

Can you combine short hydrocarbons to make long ones? Yes. You can also split long ones into shorter ones. Technically, you can stitch and split any way you like, but none of this kind of chemistry is cheap and it requires abundant energy.

Possible solutions

The next post, part II, will discuss possible solutions in more depth.

Massive batteries in current diesel and diesel-electric machines.

Hydrogen fuel cells. Hydrogen vehicles are just electric vehicles but use hydrogen for generating the electricity instead of a battery or diesel engine.

Synthetic fuel. What’s that? The chemistry to make hydrocarbons of any length has been well understood for almost 100 years. The challenge is to find the cheapest and most eco-friendly processes and sources of carbon.

Appendix: The inspiration for this post

The idea for this post comes from a recent Decouple podcast. Decouple is a great Canadian weekly podcast on energy and climate, with a somewhat nuclear bent. The host is Dr Chris Keefer. He’s a full time emergency medical doctor, so how he manages to also do a regular podcast is one of life’s great mysteries.

Growing up in Australia, I always thought of Canada as a little like us. It was bigger, but not too big and Canadians weren’t as crass as their southern neighbours or as noisy and revolting as Barry Mackenzie-style Australians.

But when it comes to engineering, Canada and Australia are very different. Canada doesn’t make a homegrown car anymore but still assembles them, while Australia gave up on even this a while back. But surprisingly, we still make trucks and tractors and some other heavy machinery.

Australians buy about 1.1 million cars a year and about 41,000 trucks. Internationally, car manufacture is all about volume and robotics. Without the volume, you can’t afford the capitalisation for a roboticised production line.

We have some terrific skills in digging stuff up and we have some biomedical smarts, but engineering? With due respect to our heavy vehicle makers, Australia is ranked 87th in the Index of Economic Complexity, wedged between Uganda and Burkina Faso and much lower than Canada at 39th. As a low-ranked country, we don’t make too many things. When you make very few things, it limits the things you can make using those things. Which in turn, limits the things you can make using those things … which limits the things you can make, etc. You get the picture.

For example, Victoria has a few tunnel boring machines (TBM) engaged in building a new metro rail system. Did we make these machines? No. Look on the website for details about these machines and you won’t find who made them. I had to send them an enquiry to find out … [watch this space]. Did they think perhaps nobody cares? Probably. We use technology, certainly. But make it? Who can be bothered when you can just buy it? Our relative lack of manufacturing makes for a lopsided knowledge profile. I’ve seen countless TV news stories featuring people claiming to have discovered this or that piece of biological or other information, while standing next to a machine that actually did the work. The real smarts are always in designing the machine that can measure and discriminate with enough accuracy to give useful results. It’s the difference between experimental and theoretical physics. Many are too ready to praise the theory and ignore the work in the design of the experiment. One of the first great experiments in climate science was the building of a bolometer, a device for detecting and measuring heat. The inventor, Samuel Langley, an American astronomer, built one in 1880 which could detect the body heat of a cow 400 metres away.

Canada is a long way behind places like Thailand, Poland, Japan, Switzerland or even Mexico, but it is well ahead of Australia. Canada has had nuclear power for decades. And they didn’t just assemble US designed reactors, they designed their own reactors and built them.

Canadian (CANDU) nuclear reactors run on natural uranium; meaning they don’t need the usual enriched fuel. They can be refueled while running. Very clever stuff.

The anti-nuclear movement has certainly had some impacts in Canada, but the tide has swung back towards nuclear as people have realised the profound problems in trying to scale renewables for a robust grid.

So the Canadian government recently stumped up a billion dollars for Small Modular Reactor (SMR) development and deployment.

This post might be of interest https://www.artberman.com/2022/11/17/energy-aware-4-the-devil-is-in-the-diesel/

Thanks Geoff. It is strange how banning/eliminating fossil fuels is so popular and yet there is almost no curiosity in the populace about what they are and how they work.

On the question of decline of road transport energy, engine efficiency is a factor, but also overall kilometers travelled have been in decline since the mid 2000's. Below are Australian data but a similar phenomenon has played out in other advanced economy cities. The decline reflects trends in urban consolidation (residential apartments in CBD's and offices locating in suburban hubs) and big growth in public transport patronage and expansion of PT capacity.